Hydro-X Solid Chemical Dosing System

What is a Chemical Dosing System?

Chemical dosing systems are found in all parts of water treatment, historically they have used large volume chemical storage to dose into systems for various reasons such as: reducing bacteria; reducing scale and corrosion; and to ensure systems run efficiently. There are many different types of chemical dosing systems which implement different technologies such as Hydro-Safe Chlorine Dioxide dosing systems, chemical dosing control for boreholes, cooling towers and steam boilers.

Hydro-X’s solid chemical dosing systems bring water treatment into the twenty first century. The solid chemical dosing systems are dosed using state of the art Ultra-M dosing units, removing the risks associated with storing and transporting large volumes of liquid chemicals. They are suitable for areas where liquid chemicals are not suitable such as when space is at a premium. The system has a very small footprint, and is wall-mountable, so there is no need for large chemical dosing tanks.

Our solid chemical dosing is available to treat a variety of water systems including, cooling tower, steam boiler, heating systems, potable systems and process water systems. It’s a cost-effective way to manage many systems in a way that also minimises the carbon footprint of Hydro-X and our customers as the chemicals weigh less than a tenth of the liquid chemical equivalent. The chemicals can also be sent through the post rather than ADR couriers for easier, more cost effective deliveries!

As with all chemistry provided by Hydro-X, the Hydro-X Solid Chemical Dosing range is distributed from our chemical blending facility in the UK and therefore available on extremely short lead times. This means that our customers can expect quick and reliable turn arounds which minimises their risks of bacterial growth and plant inefficiency.

Chemical Dosing with a difference

Innovative Technologies have allowed us to offer a completely new range of “Enhanced – Beyond Threshold Cooling Water Traced Solid Inhibitors”. Our range of solid chemical dosing systems have been manufactured with an aim to improve water quality and to help premises with compliance. They are suitable for use alongside:

- Boiler Systems

- Cooling Systems

Our system aims to prevent scale and corrosion (which doesn’t just affect the quality, it negatively impacts system efficiency too). The use of water treatment chemicals is paramount to maintaining a healthy system, but it can be a bit of a headache deciding how exactly these chemicals should be introduced into the system.

We understand that introducing Liquid Chemistry can complicate the process (in areas where liquid dosing is not suitable for H&S or space considerations) and are glad to provide a viable solution. By using solid chemicals in combination with an EnduroTEQ dissolver, you can replace liquid chemicals, saving space and reducing COSHH / H&S hazards in the process – see our video to the right as an example.

Features of Hydro-Solv

- This product line is not a replacement of standard chemistry – it’s there for specific situations where liquid chemistry is not practical.

- Reduces greatly the chance of splashback and water wastage – reducing H&S issues and COSHH issues.

- The Hydro-Solv packaging is easily recyclable and completely environmentally friendly (non-hazardous waste)

- Built-in Flow Control which allows you to dose exactly what the systems require – reducing chemical usage whilst offering improved efficiency of dosing.

- LEDs are clearly visible on the system which allows you to check the status of the dissolver

- Simple 2-piece design made up of sturdy components

- It’s a small, space efficient unit (especially in comparison with a chemical drum)

- Non contact level control, it’s a stationery piece of kit, and can be used with multiple bottles/discs

Benefits of Hydro-X Solid Chemical Dosing

- Improved scale and corrosion protection

- Reduced Legionella Risks

- Plant Longevity

- Saving water and Energy

- Reduced Down time

- Real time monitoring – (No manual presence required)

- Monitor control remotely

- Peace of mind

- Compliance records maintained 365 days a year every 15 seconds

- Optimisation of Health and Safety

- Continual operation of Cooling System without compromise.

Includes Advanced PTSA Tracing:

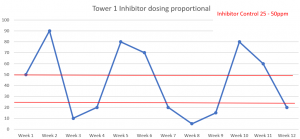

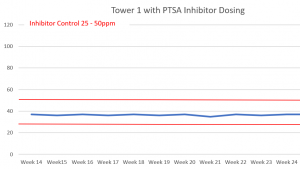

Hydro-X Solid Chemical Dosing includes PTSA technology: an advanced method of accurately dosing inhibitor to your system as a constant rather than Peaks and Troughs as detailed within the graphs below. This enhances the ability of the inhibitor to do its job as it maintains the levels as a constant and by doing this provides excellent corrosion protection, increased plant longevity, the ability to control corrosion and optimisation of chemical and water savings.

Inhibitor dosing via old antiquated proportional control – over and under dosing

Inhibitor dosing via PTSA controlled dosing – Straight line corrosion protection