Water Treatment for Closed Loop Systems

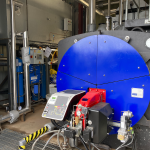

Closed loop water systems are used in a variety of applications, most commonly as industrial heating systems. Whilst these generally have greater efficiency and lower maintenance over other systems, this does not mean that they are maintenance free. Closed system water treatment helps prevent scale, corrosion, and bacteria build-up, which can cause reduced efficiency and blocked valves.

Heating and Cooling System solutions

Whether you have a closed system that is a district network or a heating/cooling network, this is often your most critical energy system. For our closed system water treatment, Hydro-X provides advanced monitoring and control solutions to complement our unique chemistry and filtration to minimise deposition and prevent corrosion. We support this with locally based and trained water treatment service experts that deliver same-day service reports to assess system performance and reduce any surprises proactively.

Well maintained and serviced closed loop water systems deliver the most efficient, and therefore cost effective utility that meets the demand of a changing environment. We use different water treatment chemicals to treat a number of potential problems and our vast experience allows us to manage the water chemistry effectively.

Scale and corrosion inhibitors are special chemicals which help by working to prevent the formation of scale in the closed system. If scale was to build up in a heat exchanger for example, it would lead to a loss in heat transfer efficiency.

In untreated systems a number of microbes/bacteria can form, of which slime forming bacteria can coat surfaces and reduce the systems efficiency. To combat this we used biocides to prevent the build up of bacteria which if left unchecked can be problematic.

> Talk to us today about your closed system water treatment requirements

> View our other Water Treatment services

Issues Affecting Closed Water Systems

There are several key issues that can affect closed water systems:

Corrosion

Water can contain components that lead to chemical reactions with the pipework, which can then cause leaks, blockages, and affect water quality. Generalised corrosion could occur throughout the system as a whole, whereas localised corrosion builds up in concentrated areas.

This can damage the equipment, as well as lead to lower water pressure due to restricting water flow. If left untreated for long enough, it can shorten the lifespan of specialised systems.

Debris Build Up

Debris can build up in closed water systems despite them not being open to the outside. This can come from corrosion and rust that breaks off, as well as improper filtration and biofilms that can grow over time.

Debris can damage closed systems and even lead to system failure in the long run. Tackle it early with Hydro-X.

Microbiological Contamination

Microbial growth is common in closed systems, and can accumulate on heat exchangers and other components. It can cause significant blockages in closed systems, reducing water flow and increasing energy and maintenance costs.

Oxygen Ingress

Oxygen can enter closed water systems via leaks, system top-ups, and even in regular maintenance activities. It can contribute to corrosion and microbial growth, in turn affecting the efficiency of systems and potentially leading to long-term, expensive damage.

Scaling

While scaling in closed water systems is much less severe than in open systems, it can still occur if hard water is used to fill the system. A build up of scale can reduce heat transfer and increase energy bills, contribute to blockages, and trigger corrosion.

Closed System Water Treatment Options

Scale And Corrosion Inhibitors

Scale and corrosion inhibitors prevent the buildup of limescale and corrosion in closed water systems. At Hydro-X, we employ powerful corrosion and scale inhibitors to prevent scale and rust building up in sensitive closed systems.

Hydro-Net Closed System Remote Water Monitoring

No matter where you or your company is based, our closed system remote water monitoring solutions ensure you know your water quality. If anything changes, your system will alert you and action can be taken straight away.

Our water monitoring systems can detect temperature changes, pH changes, levels of chemicals such as bromine and chlorine, how much dissolved oxygen is in the system, and more.

Bifipro Copper Silver Ionisation

Here at Hydro-X, we tackle contaminated water with Bifipro Copper Silver Ionisation. Whereas disinfectant products can bring COSHH risks, Bifipro Copper Silver Ionisation uses the naturally antimicrobial properties of silver and copper to eliminate common contaminants such as legionella, bacteria, and other contaminants.

Closed Water Treatment From Hydro-X

Since our beginning in 1984, Hydro-X have been dedicated to providing bespoke water treatment solutions to specialist industries. Our team is built from highly trained experts who proactively respond to any risks they may find, ensuring reports are completed the very same day and any potential risks are addressed before they become a significant issue.

Get in touch with our expert team today to discuss your closed water treatment needs.

Closed System Water Treatment FAQs

Why Do Closed Water Systems Still Require Water Treatment?

Although closed systems are sealed, they are still susceptible to issues such as corrosion, bacterial growth, sludge formation, and scaling. Contaminants can enter during installation, through make-up water, or from oxygen ingress over time.

Without proper water treatment, these issues can reduce system efficiency, cause blockages, and lead to costly repairs or breakdowns.

How Often Should Closed Loop Water Be Tested?

Closed loop systems should be tested quarterly (every 3 months) as a minimum standard. However, for newly commissioned systems or those with known issues, monthly testing may be more appropriate.

Annually, more in-depth lab analysis should be carried out to check for metals, bacteria, and inhibitor levels. Regular testing ensures early detection of corrosion, scaling, or microbial activity, so you can address it quickly and prevent any further damage to your systems.

How Should Closed Water Systems Be Maintained?

Proper maintenance of closed systems includes:

- Routine water testing to monitor pH, conductivity, and inhibitor levels

- Maintaining chemical dosing – such as corrosion inhibitors, oxygen scavengers, and biocides where needed

- Eliminating leaks and oxygen ingress, which can introduce contaminants

- Minimising make-up water to reduce dilution and contamination

- System flushing and cleaning during commissioning or after contamination

- Maintaining documentation for compliance and trend analysis