Closed Loop Water Systems – The Scale of the Problem.

Heating and Chilled systems are the motorways which transfer heat energy around buildings across the world. They move energy by pumping water around buildings to interfaces which exchange heat: i.e. give out heat – radiators, air handling units etc; or remove heat; air conditioning. It’s essential to manage these closed loop water systems proactively to avoid significant unbudgeted costs and to maintain energy efficiency.

Heating and chilled systems often go unnoticed until something fails – which is too late!

Why is Water used in Closed loop Systems?

Water is broadly used due to its high specific heat capacity (it can hold lots of energy) and its availability (its everywhere where we have buildings). However, water brings with it issues that can cause heating and chilled systems issues.

When water is added to these systems, it carries dissolved oxygen, scale, sediment and bacteria. All these contaminants can cause issues for systems which will make them run inefficiently and potentially fail. This means substantial unbudgeted costs to all involved in managing the buildings and maintaining them.

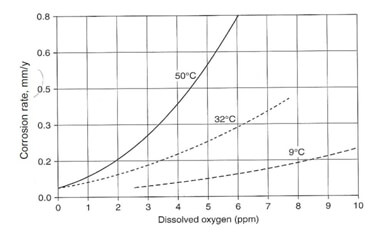

Dissolved Oxygen in closed loop water systems (heating and chilled):

When systems top up frequently (leaks, or other losses of water) the freshwater which is added to them carries dissolved oxygen. This enters the system and heats up; the oxygen then looks to escape the water and oxidise to something in the system.

This can be the metals in the system if they are not protected by suitable inhibitors like the Hydrocor range. When the metals oxidise they create a brittle layer on the inside of the pipe which will eventually corrode through the pipework and create leaks in the system.

How do you measure dissolved oxygen concentration in water?

Installing smart monitoring equipment like the Hydro-Net range will instantly notify users via email and SMS of any change to the levels of dissolved oxygen in a system. Thus improving the overall maintenance and measurement of the water in the closed loop system, in a convenient way.

Water Scale:

Scaling is a natural occurrence in heating and chilled systems and can be difficult to monitor. It occurs when a system loses water and introduces fresh water with high levels of hardness present (magnesium and calcium carbonate).

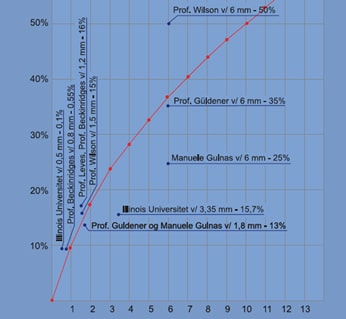

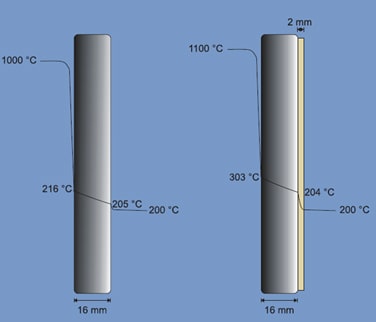

The hardness in the system will deposit itself to the surfaces of the system – often finding its way to the hottest parts, the boiler! When the scaling is present, it reduces system efficiency – around 10% increase in fuel consumption per 1mm of scaling.

What can Water Scale cause in closed loop water systems?

This build-up of scale can lead to kittling in the boilers and increasing the temperatures of the metals in the boiler heat exchangers. It can cause unnecessary stress on the system and, can also lead to premature failure. To manage scaling it is advisable to have an ion exchange softener on the fill line to the heating and chilled system.

How does sedimentation affect water?

Build-up of sediment in heating and chilled systems can create several issues. Deposits can encourage under deposit corrosion, promote the growth of bacteria, reduce the flow of water, and reduce heat exchange efficiency. This means problems with premature failure of the system, plant not operating correctly, e.g. cold spots on radiators, air conditioning fan coil units not providing cool air.

This will lead to unbudgeted costs for repair/replacement and an environment that provides sub-par conditions for employees and customers. To avoid these conditions its important to filter out sediment in the system by using side-stream filtration like the Hydro-Fil range. As recommended by BSRIA BG 29 and BG 50.

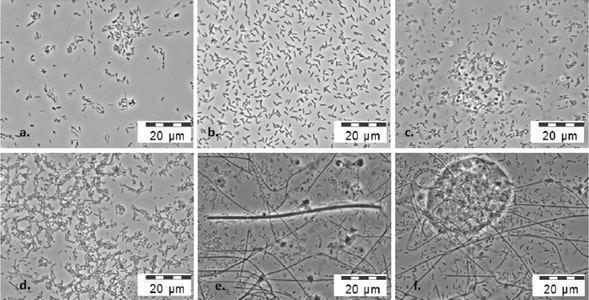

Bacteria in Water:

Bacteria finds its way into heating and chilled systems from the make-up water – it then grows where the conditions favour it. These include under sediment; in scale; in low flow areas; in biofilms; where the temperature is favourable. Bacteria can cause significant failures of pipework and assets.

They produce conditions which will corrode through pipework rapidly and can insulate systems at a rate of ten times more insulating than hardness scale. All these issues lead to increased costs in replacement of pipework and assets and increased energy costs where bacteria is present.

How to remove the chance of bacteria growth in closed loop water systems

To avoid bacterial growth in heating and chilled systems:

- It’s important to start with a clean system – this relies on good cleaning when the system is installed.

- Maintain it in a clean state – installing side-stream filtration like the Hydro-Fil range – recommended by BSRIA BG 29 and BG50.

- Ensure there is suitable flow through all parts of the system – through suitable commissioning. Ensuring there is a suitable biocide dosing regime like the Hydrocid range of biocides.

Summary:

Closed Loop Water Systems (Heating and Chilled) will often go unnoticed in buildings until something goes wrong. However, there must be proactive management of these systems to avoid unbudgeted costs and maintain energy-efficient systems. Ensuring system water quality is maintained is key to keeping the systems running as designed.

- Regular checks of chemistry and bacterial levels gives a good indicator to the current status of the water; these checks ensure the levels of inhibitors like the Hydrocor range are at the correct levels.

- Installing equipment like the Hydro-Fil range will maintain good water clarity in line with BSRIA BG29 and BG50.

- Installing instant monitoring equipment like the Hydro-Net to give instant feedback if the heating or chilled water quality changes.

- Automatic dosing to ensure levels of inhibitor are maintained.

- Biocide dosing when bacteria is found using the Hydrocid range.

If you have any enquiries, you can get in touch by filling one of our contact us forms or calling 01909 565 133.

Written by Jon Greaves.

Jon has 13 years’ experience in the water

treatment industry. He has worked in Various

roles in Hydro-X through Engineering and

Management over the last 13 years.

Jon has worked with CIBSE as an author of

CIBSE CP1.2 for District Heating Networks and

has experience with improving efficiency

heating and cooling systems.

Connect with Jon on Linkedin.